Fig. 1: Announcement in CARPENTRY & BUILDING magazine, October, 1883

This study is focused

on a series of spiral screwdrivers patented by Isaac Allard, F. A.

Howard,

and J. W. Jones and manufactured by the latter two of these men.

The earliest examples of

the racheting screwdrivers and the simplest (clockwise only) versions

of

the Archimedean screwdrivers begin to appear in tool catalogs and

related

literature in the late 1880s and the early 1890s (see Fig. 1). The

spiral

screwdrivers with a provision for some sort of mechanical release on

the

return stroke, with a reversing feature and with a racheting feature in

combination with the mechanical release begin to show up about ten

years

later.

Fig. 1: Announcement in CARPENTRY & BUILDING magazine, October, 1883

The earliest documentation for a spiral screwdriver offered for sale, which I have been able to locate, is a notice in the "Novelties" section of the October, 1883 CARPENTRY AND BUILDING announcing the availability of the Allard Spiral Screwdriver manufactured by F. A. Howard of Belfast, Maine. Although there are earlier patents for some screwdriver features such as ratchets, the 1868 Allard patent is the earliest I have been able to find for a spiral screwdriver.

The quaint discourse on

spiral

screwdrivers in the 1895 & 1897 CHARLES A. STRELINGER catalogs

mentions

that the company had received requests for spiral screwdrivers as early

as 1877. The inquiries came from persons who had seen such tools and

wanted

to know where they could be procured. After investigation, the

Strelinger

Co. concluded that the tool sought was the "Allard", which they

subsequently

began to carry in stock. Since they mention that their first observance

of one of these tools was from a "newcomer from the East," and that a

company

of their significant size had difficulty obtaining even a sample, it

might

be concluded that the tool was not marketed initially through normal

commercial

channels. Indeed, the above 1883 notice states that they are available

not only through the "hardware trade" but by mail from the

manufacturer.

The excerpt from the Strelinger catalog follows:

SPIRAL SCREW DRIVERS This article is intended not so much as a history of Spiral Screw Drivers, but as a history of our experience with Spiral Screw Drivers. At different times during the years 1877 and 1878 we had a number of calls for a screw driver that operated by pushing. The inquirers had heard of it, and an occasional inquirer stated that he had seen one, but we could in no conceivable way locate one of these drivers, or obtain a sample, and we had about come to the conclusion that the Spiral Screw Driver was a "Will o' the Wisp" (a sort of fairy tale as it were), and existed only in the imaginations of the inquirers, when one day a cabinet-maker employed by the Pullman Car Co. came into our store, and incidentally informed us that one of his shopmates, a newcomer from the East, had one of these drivers. At some little pains and expense we secured this driver, and were thus enabled to get the name and address of the manufacturers. It was the Allard Spiral Screw Driver and quite similar in design and construction to the present style. The price at that time being $3.00 each. Two or three years later the supply ceased. The only reason we could learn was that the demand had grown so, that the maker was unable to supply it, on account of insufficient machinery, and so had stopped making them entirely in order to build more machinery. We always thought this was a very queer proceeding, but, at any rate, other styles were brought out from time to time, and this class of screw driver is almost as well known - if not quite as commonly used - as the ordinary style.The Spiral Screw Driver ranks among the most wonderful labor-saving tools ever invented, and this method of driving small and medium sized screws is an entire revolution. It saves fully two thirds of the time, as it will drive screws in either soft or hard wood in one-third of the time taken by an ordinary screw driver. It is operated by simply pushing on the handle.

CAUTION: BE SURE AND OIL OFTEN. THERE IS GREAT FRICTION, AND THE TOOL WILL LAST TWICE AS LONG IF PROPERLY OILED.

In the past ten or fifteen years we handled eighteen different makes of Spiral Screw Drivers, including thirty-two different sizes and styles. Among them the Allard, Baush, Rapid, Ellrich, Forest City, Eureka, Eclipse, Electric, Goodell, Howard-Allard, Jones, Haberle, Mueller, Millers Falls, Prior's, Reed's, Shaver and Wright.

At the time of compiling this catalog we had in stock eleven of the foregoing makes and styles (the other six having been discarded on account of their having no special merit). In order to avoid multiplicity and confusion we found it necessary to cut down this line, retaining only such as were, in our judgment, the best in their respective classes. As all of the eleven styles had more or less merit, it was not altogether an easy matter to decide which should be kept, and so every point had to be gone over and considered carefully.

Without going into details too much,and perhaps for the reason of demonstrating how thoroughly all the various tools in this catalogue have been considered, we may explain why two or three well known Spiral Drivers are not shown here. The Forest City Spiral Screw Driver is altogether the most ingenious and complete tool in this line that we have ever seen. It has more motions than any other, and many improvements, but the mechanism is rather complex. The chuck for holding the bits is insufficient, and we do not believe that it has either the strength or wearing qualities of the others.

The Mueller Driver is a strong, practical tool, well made, but for the work for which a Spiral Screw Driver is best adapted, we think it is too heavy.

There have been four improvements since the Allard was first perfected. First, the chuck or holder by which the tools could be changed, so that different sizes of bits could be used. Second, the right and left spiral (see Fig. 3448), so that the tool could be run either hand. Third, the loose collar (see Fig. 3447), which remains stationary while the shaft revolves; and Fourth, the continuous motion in one direction. There is but one driver that contains all of these points -- the Forest City -- and this, for reasons stated above, we felt obliged to leave out. The No. 22 (Fig. 3448) contains the three points first named.

TO SUM UP - We believe that the line of Spiral Screw Drivers shown here embraces all the best qualities which can possibly be found in this class of tools.

The original patentee,

Isaac Allard (1822-1884) began work as a watchmaker in 1840. Business

directory

listings for Allard for the years 1849-1882 indicate that in addition

to

first being listed as "watchmaker and repairer", he moved on to being

listed

as "notary, machinist, jeweler, silver and silver plate dealer, fancy

goods

dealer". One might speculate that his "upward mobility" might have had

something to do with his marrying the daughter of the machinist,

watchmaker

and "fancy goods dealer" to whom he apprenticed.

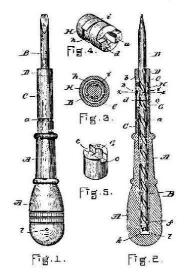

It is doubtful if this original version was actually manufactured; I am not aware of any examples. Catalogs from the 1880s show illustrations identified in one instance as the "Allard's Patent" model and in another with the generic designation - "The Spiral Screwdriver." The appearance of these, however, more closely resembles the 1874 Allard patent and the examples in Fig. 1 and Fig 4.

Fig. 2: 1868 Allard patent illustration.

The force of the spring when released is intended to drive the screw.

Mr. Howard's 1893 house still stands in obviously well maintained condition on Belmont Street in Belfast.

Fig. 3: 1874 Allard patent illustration.

Note the reduced diameter of the shaft for holding the bit against

the screw; this was replaced by a free collar on some of the later

models.

Fig. 4: Example #1 (c.1874-1892)

signed: F. A. Howard / - Maker - / Belfast, Me.Allard's Pat. / Aug.

4 1868 / Nov. 24 1874

It should be noted that both the above patents predate significantly the 1882 A. H. Reid patent for his bit stock - advertised as the "Lightning Brace" but in reality a screwdriver - of which we see so many examples. Even by 1882 the Reid model did not incorporate any mechanical means for releasing the shaft on the return stroke but instead relied upon the driving hand shifting to the inner, free-wheeling handle.

To gain some perspective

on the place of Allard/Howard/Jones, consider a few other patents for

spiral

screwdrivers and their patent dates - the well known Decatur Coffin

Co./Eureka/C.

H. Olson (1884), J. R. Doolittle (1886), H. Mueller (1889), A. D. &

H. E. Goodell (1890), G. E. Gay & J. H. Parsons (1892) and Zachary

Furbish assigned to North Brothers (1895). The one patent which comes

closest

in date, is that of William Hofer, New Haven, Connecticut (1869) for a

model which very closely resembles the 1884 C. H. Olson.

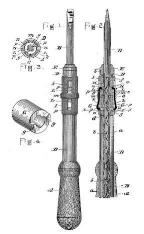

Fig. 5: 1892 Howard patent illustration.

Improvements added are a friction spring for the clutch and a spindle

lock in the closed position

Fig. 6: Example #2 (c.1892-1894)

signed: F. A. Howard / - Maker - /Belfast, Me. / Pat. Aug 4 1868 /

Nov 24 1874 / Mar 1 1892

The indefinite engagement of the clutch and nut was apparently found to be a problem in the examples in Fig. 4 (example 1) & Fig. 6 (example 2) when held with the bit pointed downward. In this position gravity would pull the clutch nut toward the bit and away from the clutch. This shortcoming prompted the need for some means of ensuring consistent engagement of the clutch and prompted the introduction of an expanding spring surrounding the clutch nut exerting friction to prevent it from dropping. Strangely however, the latter example, even though showing the 1892 patent date, does not include the friction spring.

The other significant addition in this improved patent was a notch in the rear end of the spindle which engaged with a crosswise pin in the handle to provide a positive lock for the shaft and thus prevent the shaft from rotating and forcing the handle out when turned counterclockwise for screw removal.

This example (Fig. 6 -

example

2) must be considered earlier than Fig. 7 (example 3) & Fig. 8

(example

4) because it does not include the "son" in the name.

Fig. 7: Example #3 (c. 1895-1901)

signed: Made by / F. A. Howard & Son / Belfast, Me / U.S.A/ Pat.

Mar 1 1892

The friction spring to insure engagement of the clutch is included in the examples pictured in Fig. 7 (example 3) & Fig. 8 (example 4).

Although the one-piece, non-removable bit in Fig.

8 (example 4) would appear to come chronologically before the removable

bit models shown in Fig. 6 (example 2) and Fig. 7 (example 3), it must

be placed later because of the inclusion of "Son" in the name.

Fig. 8: Example #4 (c. 1895-1901)

signed: Made by / F. A. Howard & Son / Belfast, Me / U.S.A. / Pat.

Mar 1 1892

Examples 3 & 4 are signed the same and apparently fall into the same time period of manufacture. Two characteristics set example 4 apart from the others: (1) It was manufactured without the removable bit which all the other models except the earliest include. (2) It was manufactured with only 2 spiral grooves in contrast to the 4 spiral grooves on all the other uni-directional models.

These two characteristics

seem to argue that this model was the low priced, "competitive" model,

whereas example 4 was the then standard model, with the improvement of

the addition of a free turning ring/grip behind the bit chuck to aid in

guiding the bit and holding it in place for the withdrawal stroke.

These

two models (examples 3 & 4) are not illustrated or listed in any of

the catalogs and related literature studied.

It is curious to note that this patent by J. W. Jones for the earliest reversing spiral screwdriver and the above patent by F. A. Howard for improvements in the uni-directional spiral screwdriver were both granted on the same date; furthermore, each of these inventors served as a witness to the other's patent description (not included here).

Only the scant information of a Belfast directory listing as "machinist" has been found for J. W. Jones. Since his name does not appear on the tool even after his patents were granted it will have to be assumed that he was an employee of F. A. Howard.

For comparison it can be

noted that the North Brothers patent for the reversing feature (double

spiral on the same shaft) was granted in 1895 and the Goodell patent

with

the reversing feature (right hand spiral telescoping into the left hand

spiral) was granted in 1897 and both were probably not offered for sale

until about 1898.

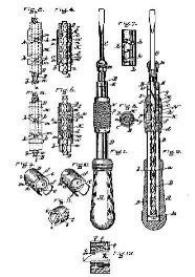

Fig. 9: 1892 J. W. Jones patent illustration.

First model with reversible feature.

Fig. 10: Example 5 (c. 1892-1895)

signed: F. A. Howard / - Maker - / Belfast, Me. / Jones' Pat. / Mar

1 1892

Fig. 11: J. W. Jones 1895 patent illustration.

Jones' Improved Reversible Model

Fig. 12: Example 6 (c.1895-1901)

signed: Made by / F. A. Howard & Son / Belfast, Me U.S.A. / Pat'd

July 23 95

Fig. 13: Left: Goodell Pratt chuck nut; Right: Howard/Jones chuck

nut)

Note similarity of chuck nut on Goodell Pratt and Howard/Jones

screwdrivers.

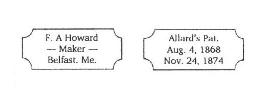

The style of the

cartouche

(Fig. 14) with inward rounded corners used for the signature and patent

information begun by Howard was continued in the same style through all

of the examples studied here.

Fig. 14: Style of Allard/Howard/Jones markings

I have the feeling that

many

of the features of the Allard/Howard/Jones screwdrivers are in some way

carried on in those later manufactured by the firms of Goodell

Brothers,

Goodell Pratt and Millers Falls. The similarity of the chuck nut and

the

removable bit on many of the screwdrivers manufactured by these firms

to

the style used by Howard and Jones are too striking to be coincidental.

I have been unable, at this time, to document a link with any of the

above

three firms. It is my hope that, in time, this hypothesis can be proven

and documented.

Belfast Museum, Inc., Andrew Kuby, Curator

Maine State Museum, Brian M. Sipe, Curator of Decorative Arts

Carpentry & Building, New York, David Williams Company,

October

1883

WOODWORKERS TOOLS, Detroit, Charles A. Strelinger & Co.,

Detroit, 1895

WOODWORKERS TOOLS, Detroit, Charles A. Strelinger & Co.,

1897 - reprinted by Mid-West Tool Collectors Association, 1979

Belfast and Camden Directory, Ayer, Mass., E. B. Butterfield,

1890

Vital Records of Belfast, Maine, Portland, Maine Historical

Society, 1919

1849 Mercantile Union Business Directory Part I - Maine, New

York, Pratt & Co., 1849

1855 Maine Business Directory, Boston, George Adams, 1855

Maine Register, State Year-Book and Legislative Manual,

Portland,

G. M. Donham, 1893

Williamson, Joseph, History of the City of Belfast in the State

of Maine, Vol. II, Houghton Mifflin Company, Boston & New York,

1913

WOODWORKERS' TOOLS, Philadelphia, Wm. P. Walters, 1888

Republican Journal, (Belfast, Maine), October 1, 1903 (obituary

- F. A. Howard)

Return to Spiral Screwdriver Home Page

©1992 Clifford D. Fales All Rights Reserved