After years of having seen many rules with the usual round, square, or arch joint (and the occasional other English styles) this rule with a joint which had a raised, circular fluted disk caught my eye when it was spotted in a stack of rules at a tool meet. As well as the joint which I did not recognize was the name of an unfamiliar maker. Subsequent investigation concerning both the maker of the rule and the patentee of the rule joint has proved to be an interesting subject.

|

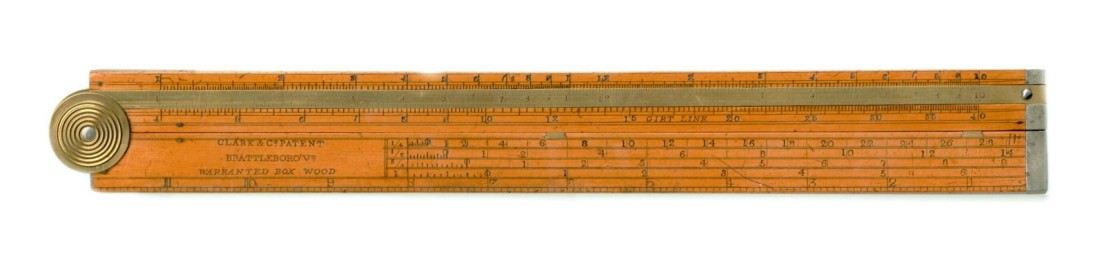

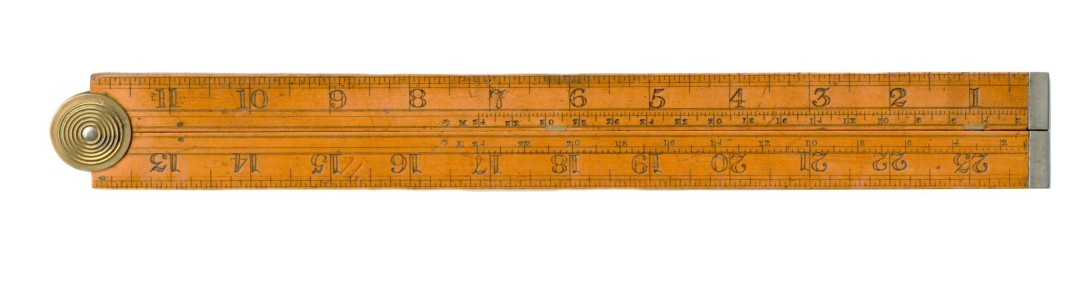

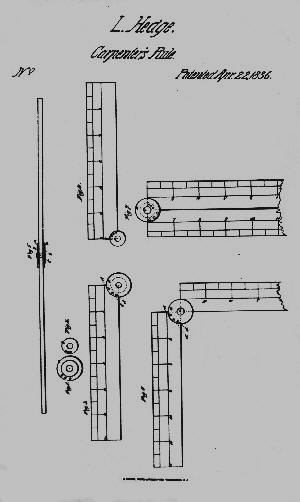

THE RULE: A two foot, two fold, bitted, with Gunter's slide. It is signed: CLARK & CO. PATENT / BRATTLEBORO, VT. / WARRANTED BOXWOOD. The leg tips are steel. Except for the joint and some minor variations in how the drafting scales and the graduations are laid out, the rule is similar to, and incorporates the features of a Stanley No. 12 or No. 27. The signature is on the side with the slide and drafting scales. It is not graduated on the two mating edges on this side but is graduated on the lower edge below the drafting scales. At first observation the joint appears to be composed only of the two brass disks raised above the surface (not let into the boxwood) and held together by a steel rivet. The pivoting action seems to result from mating circular tracks on the underside of the disks and the front and back sides of the legs. The area beyond the end of the legs between the two disks is totally open. Closer examination reveals two brass pins, which rivet the disks to one leg, and the two smaller steel disks on the underside of each of the brass disks which do not turn with the leg to which the outer disks are attached but which turn with the opposite leg. This is, of course, just what the patent drawing shows.

THE MAKER: S. Morton Clark, was one of the earliest rule makers

in New England, commencing operations in Brattleboro in 1833. After operating

for only a few years his business closed down during the economic "hard

times" of 1837. The business soon began operations again (1838) under a

name more familiar to tool collectors E. A. Stearns. Stearns was a former

employee of Clark who bought the defunct business including the factory,

machinery and stock and soon gained a reputation

for producing high quality rules. (Hubbard and Cabot give 1830 as the beginning

date of the Stearns firm but this does not seem probable.) The name of

Charles L. Mead now enters the scene; he purchased an interest in the Stearns

business in 1857 and by 1861 advertised himself as successor to E. A. Stearns,

but continued to sell his product under the Stearns name until 1863 when

the firm was acquired by S. R. & L. Co.

THE MAKER: S. Morton Clark, was one of the earliest rule makers

in New England, commencing operations in Brattleboro in 1833. After operating

for only a few years his business closed down during the economic "hard

times" of 1837. The business soon began operations again (1838) under a

name more familiar to tool collectors E. A. Stearns. Stearns was a former

employee of Clark who bought the defunct business including the factory,

machinery and stock and soon gained a reputation

for producing high quality rules. (Hubbard and Cabot give 1830 as the beginning

date of the Stearns firm but this does not seem probable.) The name of

Charles L. Mead now enters the scene; he purchased an interest in the Stearns

business in 1857 and by 1861 advertised himself as successor to E. A. Stearns,

but continued to sell his product under the Stearns name until 1863 when

the firm was acquired by S. R. & L. Co.

THE PATENT: A search for a patent under the name of Clark yielded no results. However, when looking in the 1790-1837 index of patents under the category of "rules" an entry for a "Carpenter's Rule Joint" with the location of "Brattleboro, Vt." and the name of Lemuel Hedge stood out because of the Brattleboro location. A look at the drawing for the patent under this entry (April 22, 1835) quickly confirmed that this was the one being sought. This was originally a Name and Date patent which has subsequently been assigned the number 8783X. Further search of the patent records revealed page two of the two page patent description. There apparently is no way to find any information on the missing page. It, presumably, was lost in one of the early patent office fires. Lemuel Hedge was a very interesting man. With a background in blacksmithing and cabinetmaking he turned his creative mind to creating solutions for improving efficiency and accuracy in the rule making business as well as in other fields. His earliest patents were for a "springpen ruler" and a "revolving ruler"which replaced the then current, laborious process of ruling lines on paper by hand. His most significant patent relating to rules was his "dividing engine" which mechanized the previously hand executed operations of stamping graduation marks and numerals during the manufacture of rules. It has been claimed that Hedge's original dividing engine remained in use in the Stanley Rule and Level Co. plant at least as late as 1923. It has not yet been established exactly what the relationship was between Hedge and Clark. Hubbard states that in 1840 Hedge sold his interest in the business to E. A. Stearns, but Hedge must have had some sort of business relationship with Clark prior to 1838 since Clark had incorporated Hedge's patented joint in his rules and apparently used Hedge's graduating engine in the manufacture of his rules. Hedge also utilized Clark as one of the two required witnesses on his patent application. Might he have been an employee of Clark? Or a partner? or neither?

Patent Text:

NAME AND DATE PATENT

CARPENTER'S RULE JOINT Lemuel Hedge April 22, 1835

[Author's Note: When this article was published in 1987, page one was missing from the patent files and was presumed lost in one of the early patent office fires. Since then, Paul Kebabian has discovered that the complete 1835 Hedge patent does exist and has kindly provided it to the author. When time permits it will be added to this article. For now, only page two is presented.]

............for rules to my knowledge possible as follows. The common joint is composed of more or less pieces of metal, which when placed together forms a solid mass, of the thickness of the rule and is attached to the boxwood or other material composing the legs of the rule by removing a portion of their thickness to receive the joint which diminishes their strength. This joint possesses little or no elastisicity consequently as it wears it becomes loose. My improved joint is applied to the rule without removing any of its thickness to receive it which is one of the principles I claim as my invention.

The manner of forming the joints of thin plates attached to the sides of the two legs, the intervening space being filled with the substance of the rule itself instead of the more expensive mode of filling that space with metal is another principle I claim as my invention. My joint thus formed and applied possesses a degree of elasticity operating as a perpetual spring which prevents this joint from ever becoming loose.

Witnesses Lemuel Hedge

S. M. Clark

John Holland

The author would be grateful for additional information from any readers on S. Morton Clark or Lemuel Hedge.

Grateful acknowledgement is made to Roger Smith, Paul Kebabian,and Philip Stanley for direction to the references cited below.

Clifford Fales collection and photographs. Patent and patent drawing

courtesy the author.

Text and images, Copyright: ©

1997 Clifford D. Fales All Rights Reserved.